An In-Depth Review: The Comprehensive Challenges and Future Pathways for High-Temperature Lithium Metal Batteries (HT-LMBs)Introduction

- Technical Research

- Sep 4, 2025

- 3 min read

From desert grid storage and electric aviation to deep-earth exploration, numerous cutting-edge applications are driving an urgent demand for next-generation, high-energy-density batteries that can operate in harsh thermal environments. While conventional lithium-ion batteries are limited by their narrow operating temperature range (<60°C) and moderate energy density, Lithium Metal Batteries (LMBs) offer a compelling alternative with their superior theoretical energy density. However, commercializing LMBs for high-temperature applications means their inherent instabilities are dramatically amplified.

Recently, a review published in Advanced Energy Materials by Professor Husam N. Alshareef's group at KAUST provides a comprehensive analysis of the progress and challenges facing High-Temperature Lithium Metal Batteries (HT-LMBs). The work systematically details the failure mechanisms of every core and auxiliary component at high temperatures and charts a course for the future of "cooling-free" battery system design.

High Temperature: An Amplifier and Accelerator for LMB Degradation

For a lithium metal battery, a high-temperature environment is more than just an elevated operating temperature; it acts as an amplifier and an accelerator. It exponentially magnifies and quickens the challenges already present in LMBs at room temperature, such as SEI instability, lithium dendrite growth, electrolyte consumption, and interfacial side reactions. Research shows that the vast majority of LMB studies focus on room-temperature conditions, leaving a critical gap in the systematic understanding of high-temperature degradation mechanisms—a primary barrier to commercialization.

A Comprehensive Failure Analysis: Systemic Challenges from Core to Auxiliary Components

The review emphasizes that building reliable HT-LMBs requires a systems-level approach, as failure at high temperatures is an all-encompassing issue affecting every single component of the cell.

Cathode: High temperatures accelerate phase transitions and oxygen release in high-voltage cathodes (e.g., NMC), exacerbating side reactions with the electrolyte. For sulfur cathodes, heat worsens the "polysulfide shuttle" effect, leading to rapid active material loss and low coulombic efficiency.

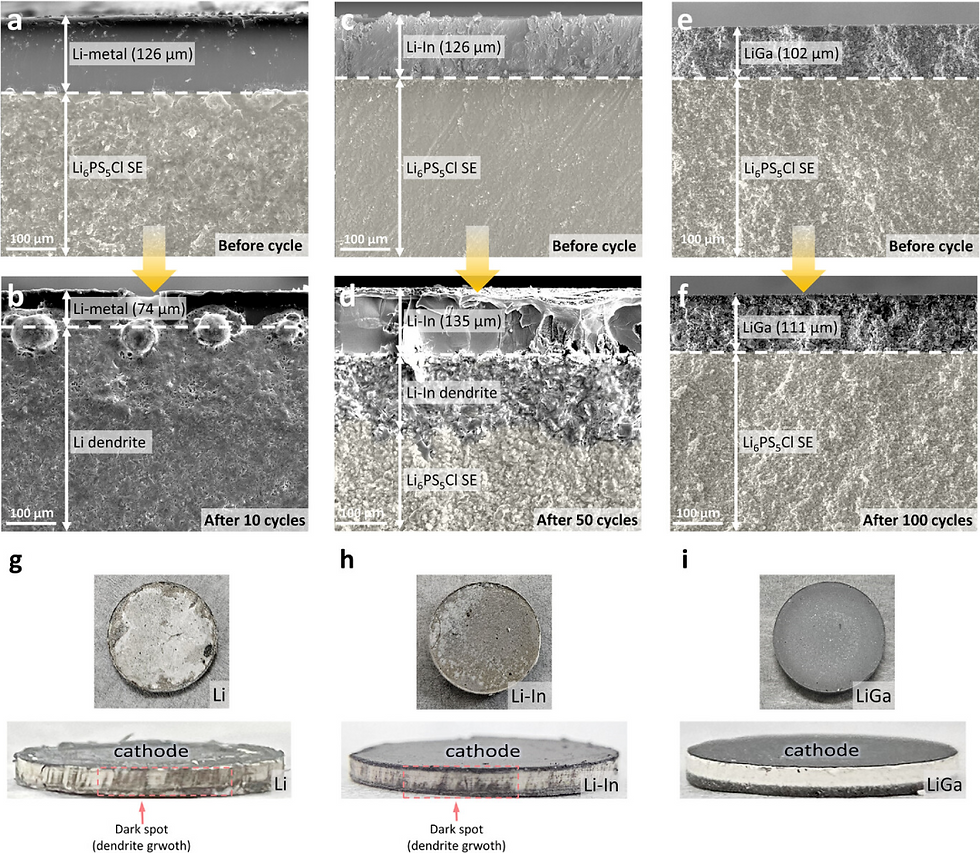

Lithium Metal Anode: Heat is a double-edged sword. While moderately elevated temperatures can aid in uniform lithium deposition, they also drastically accelerate the decomposition of the SEI layer and the corrosion of the lithium metal itself.

Analysis of lithium metal anode failure at high temperatures Electrolyte: Conventional electrolytes face issues of low boiling points, evaporation, and decomposition at high temperatures, leading to increased internal pressure and safety risks. Developing novel electrolytes with high thermal stability is a cornerstone of HT-LMB research.

Analysis of electrolyte failure at high temperatures Auxiliary Components: These are often the weakest link. Conventional polyolefin separators can melt and shrink above 100°C, causing internal short circuits. PVDF binders soften and decompose, compromising the electrode's structural integrity. Even current collectors can corrode under prolonged high-temperature operation.

The Path Forward: Strategies for Building Reliable HT-LMBs

Facing these systemic challenges, the article outlines several key strategic directions to advance the development of HT-LMBs:

Integrated System Design: The cathode, anode, electrolyte, and auxiliary components must be co-designed as an integrated system to ensure thermodynamic, electrochemical, and mechanical stability.

Development of New Heat-Resistant Materials: R&D on novel, thermally stable materials—such as solid-state electrolytes, high-concentration electrolytes, polyimide separators, and advanced binders—is a top priority.

Establishment of Standardized Benchmarks: The research community urgently needs to establish unified, rigorous performance evaluation standards and protocols for high-temperature operation (including cycle life, calendar life, and safety tests) to ensure data comparability and accelerate commercialization.

Leveraging Advanced Tools for R&D: The introduction of tools like machine learning (ML) and artificial intelligence (AI) can significantly accelerate the discovery and screening of new heat-resistant electrolyte formulations and interfacial materials.

Conclusion and Outlook

Developing lithium metal batteries that can operate reliably in high-temperature environments is a strategic breakthrough needed to meet the energy demands of future extreme applications. The complexity of this challenge requires a shift from single-material innovation to multi-component, multi-disciplinary systems engineering. A deep understanding of the fundamental science within the battery at high temperatures, combined with standardized testing and advanced tools like AI, will be the key to finally realizing robust, safe, high-energy-density battery systems that require no external cooling.

While the path to reliable high-temperature lithium metal batteries is still challenging, the advancement of high-energy-density battery technology is happening now. As a pioneer in this field, LIMX Power has already achieved mass delivery of 450-500Wh/kg lithium metal batteries. If your application has demanding requirements for energy density, we invite you to contact us via our homepage to discuss your needs with our experts.

Literature Information

Dong Guo, Zixiong Shi, Jehad K. El-Demellawi, et al., and Husam N. Alshareef, Lithium Metal Batteries for High Temperature Environments, Adv. Energy Mater., https://doi.org/10.1002/aenm.202502943

Comments