Not All Lithium Foils Are Created Equal: Unveiling the Impact of Surface Passivation and Crystal Orientation in Commercial Lithium Anodes

- Technical Research

- Nov 27, 2025

- 3 min read

Introduction

Lithium metal is hailed as the "Holy Grail" of battery anodes due to its ultra-high specific capacity and lowest electrochemical potential. However, a critical variable is often overlooked in laboratory research: the significant quality variation among commercially sourced lithium foils. These differences—ranging from surface roughness and passivation layer composition to crystallographic orientation—are often obscured by opaque manufacturing processes but directly dictate battery performance and cycle life.

Recently, a team led by Prof. Feifei Shi at Pennsylvania State University published a study in ACS Applied Energy Materials, conducting a comprehensive "physical examination" of five leading commercial lithium metal anodes. The research not only reveals their significant physical and chemical heterogeneity but also establishes a direct correlation between these microscopic properties and macroscopic battery performance, providing a vital basis for the standardized evaluation of lithium anodes.

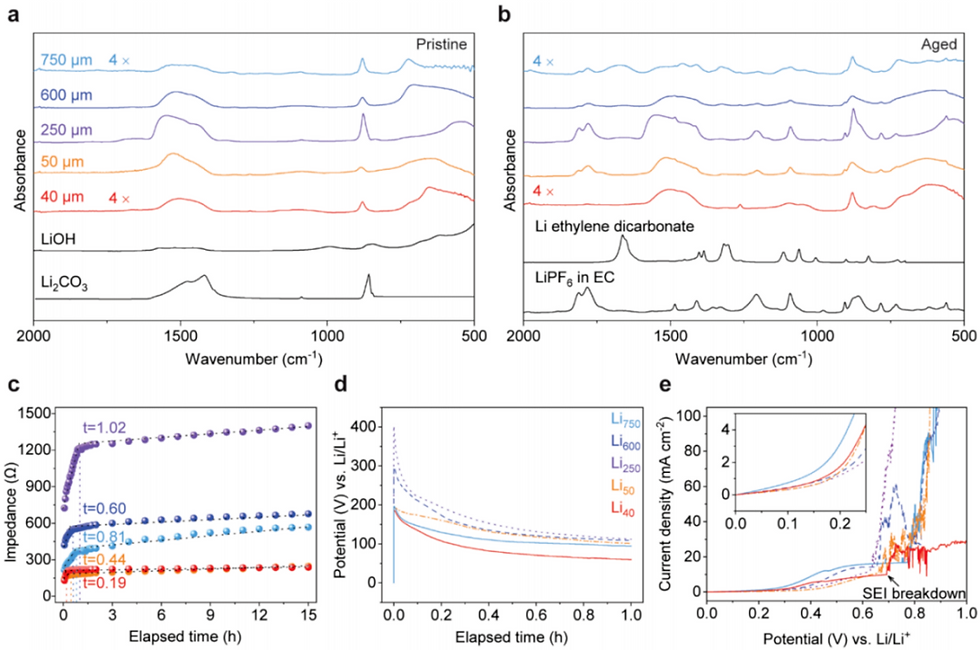

Physical and Chemical "Fingerprints": Roughness and Passivation Layers

The study first analyzed the morphology of five commercial lithium foils of varying thicknesses (Li40 to Li750). Results showed that manufacturing processes (like mechanical extrusion and rolling) leave slip lines and microscopic defects, causing huge variations in surface roughness. This directly affects subsequent local current density distribution.

More critical differences lie in the surface "passivation layer." XPS depth profiling revealed that all foils are covered with complex passivation films, primarily composed of Li₂CO₃, LiOH, and Li₂O.

LiOH/Li₂O: These components are generally detrimental to forming a high-quality SEI.

Li₂CO₃: Conversely, a moderate Li₂CO₃ layer helps form a more stable and uniform SEI.

Surface "Freshness": The study found that Li40 samples had the highest metallic lithium content and the "freshest" surface; while Li600, despite being rough, offered good passivation protection due to a thicker Li₂CO₃ layer.

Crystallographic Orientation: The Invisible Force Shaping Deposition

Beyond surface chemistry, crystallographic orientation (texture) is another often-ignored factor. XRD analysis revealed significant disparities:

(110) Texture: Thinner Li40 and Li50 foils exhibited a strong (110) preferred orientation.

(200) Texture: Thicker Li250, Li600, and Li750 foils predominantly showed a (200) texture.

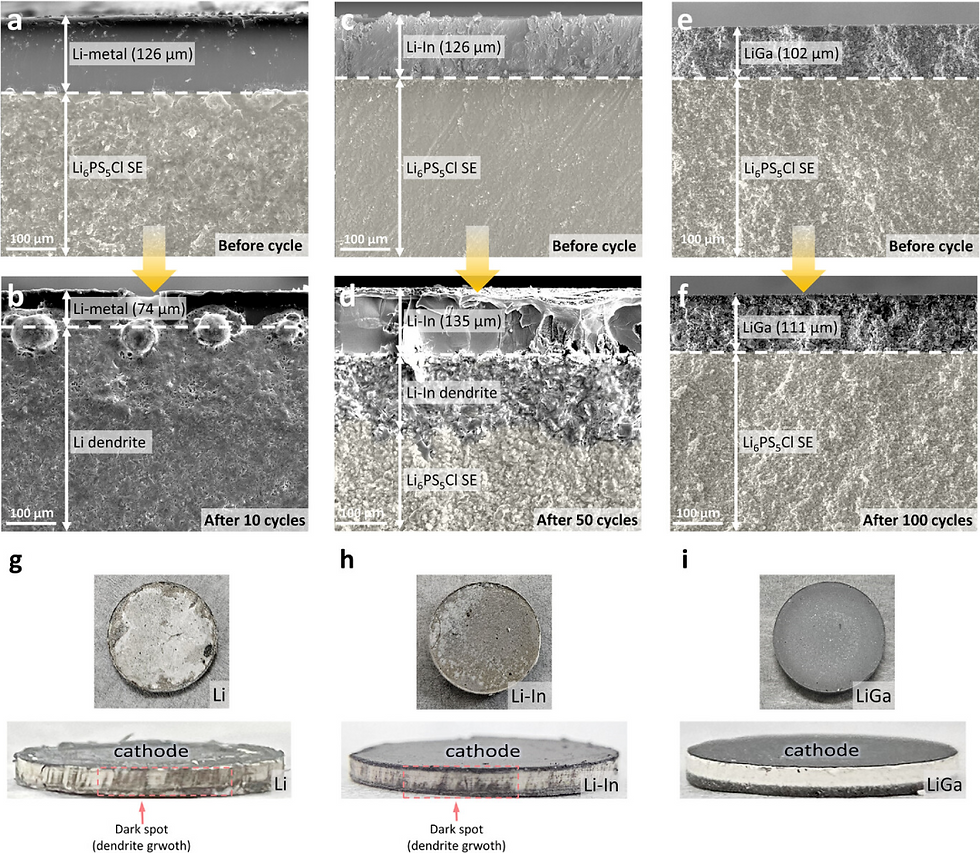

Electrochemical tests confirmed that lithium foils with a (110) texture induce more uniform and dense lithium deposition via substrate effects, significantly suppressing dendrite growth.

Structure-Property Correlation: What Makes a "Good" Lithium Foil?

Through validation in Li||NCM811 full cells, the study established a clear structure-property relationship.

Top Performer (Li40): Thanks to its smooth surface, high metallic content (favoring low-impedance SEI formation), and unique (110) crystal texture, Li40 demonstrated the highest capacity retention (91.15% after 200 cycles) and Coulombic efficiency (99.82%).

Underperformers: Samples with poor surface SEI quality or dominant (200) texture suffered from severe dendrite growth, leading to high overpotentials and short lifespans.

Conclusion & Implications: Establishing a "Gold Standard" for Lithium Anodes

This work serves as a wake-up call for battery researchers: the choice of baseline lithium foil is critical.

Based on the findings, the authors propose a profile for the "ideal" lithium metal anode:

Surface Chemistry: A surface with high metallic content or covered by a uniform Li₂CO₃ passivation layer.

Crystal Structure: A distinct (110) epitaxial texture.

This discovery underscores the urgent need to establish standardized manufacturing and evaluation protocols for lithium metal to eliminate raw material variability as a confounding factor in research, accelerating the practical application of high-energy lithium metal batteries.

The exploration of next-generation anode materials requires both deep scientific understanding and manufacturing excellence. In this arena, LIMX Power is committed to producing high-performance anode materials to the most rigorous standards, having now mass-produced and commenced bulk deliveries of the industry's first all-silicon-carbon anode battery.

Literature Information

Hanrui Zhang, Dongliang Chen, Jianwei Lai, and Feifei Shi*, Understanding the Surface Passivation and Crystallographic Orientation Effects of Commercial Lithium Metal Anodes on Battery Performance, ACS Appl. Energy Mater., https://doi.org/10.1021/acsaem.5c03229

Comments