Opening the "Black Box" of Solid-State Batteries: Prof. Xueliang Sun's Team Reviews the Critical Role of Advanced In-Situ CharacterizationIntroduction

- Technical Research

- Nov 4, 2025

- 4 min read

All-solid-state batteries (ASSBs) are widely recognized as a key contender for next-generation energy storage due to their immense potential for high safety and energy density. However, their path to practical application is still fraught with critical challenges rooted in solid-solid interfaces. For a long time, our understanding of the dynamic failure processes inside these batteries has been limited. Traditional characterization methods often only permit a "post-mortem" analysis after the battery has failed, failing to capture the instantaneous evolution under real operating conditions. This has made R&D feel like fumbling inside a "black box."

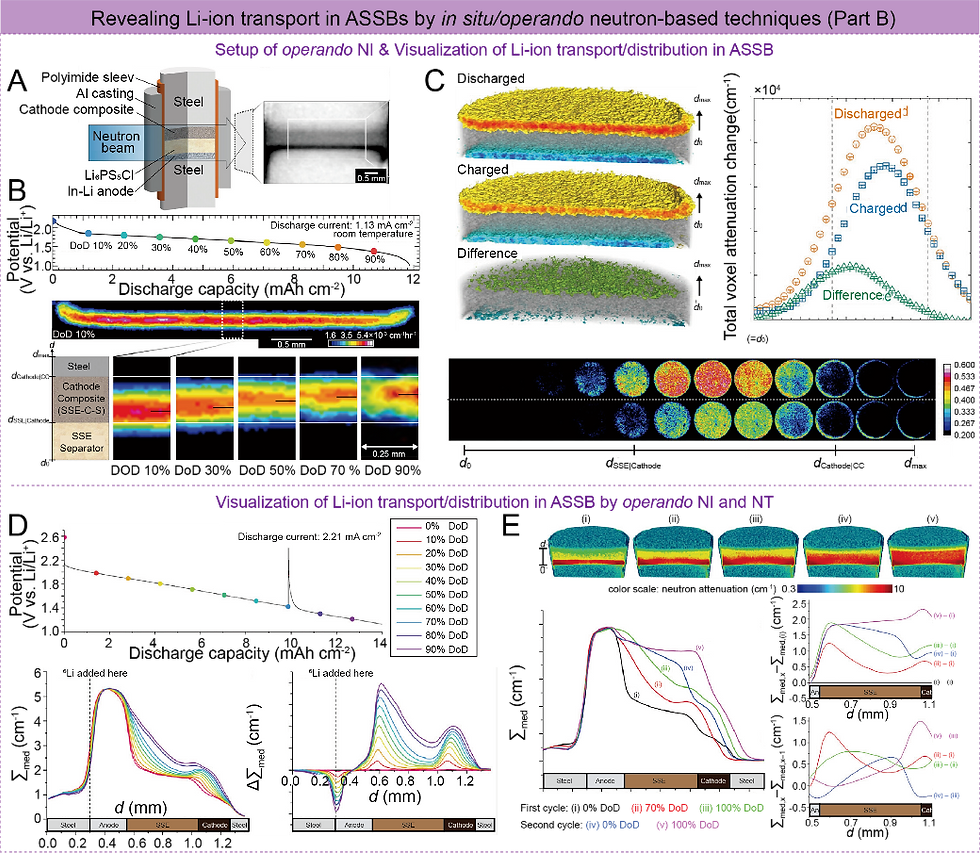

Recently, Prof. Xueliang Sun, Prof. Changhong Wang, and Prof. Yipeng Sun from the Ningbo Institute of Technology, Eastern, along with a consortium of top institutions, published a major review in Advanced Energy Materials. This work systematically summarizes how to use synchrotron X-ray and neutron techniques to achieve multi-scale, in-situ, and real-time "X-ray vision" inside all-solid-state batteries.

The "Achilles' Heel" of Solid-State Batteries: The Interface

The performance and lifespan of an all-solid-state battery are almost entirely dictated by its complex internal solid-solid interfaces. These coupled electro-chemo-mechanical challenges form the "Achilles' heel" hindering their development:

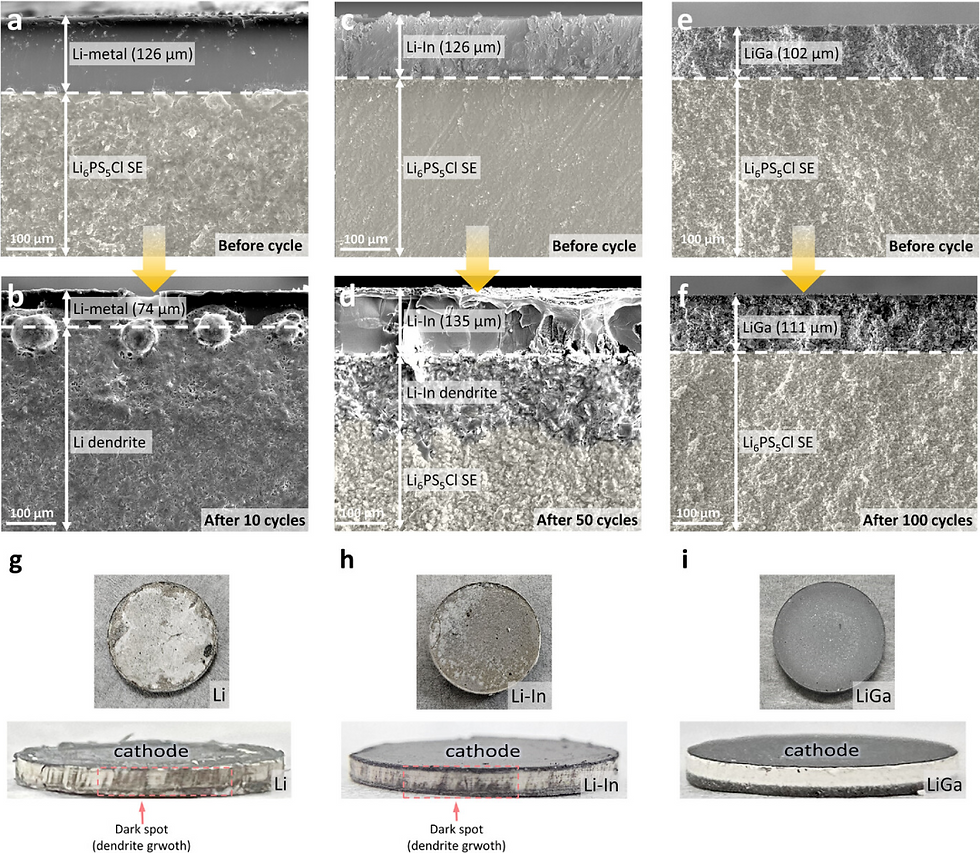

Anode Side: Lithium dendrite growth, interfacial voids from non-uniform stripping, and side reactions between lithium and the solid electrolyte all lead to interfacial failure and short circuits.

Cathode Side: Limited contact points between active materials and the electrolyte cause high internal resistance; volume changes during cycling lead to particle cracking and contact loss.

Electrolyte Bulk: The brittleness of ceramic electrolytes makes them prone to cracks, which provide a physical "shortcut" for lithium dendrites.

To precisely solve these problems, we must shift from "observing phenomena" to "analyzing mechanisms." Advanced in-situ characterization is the critical bridge to opening this "black box" and making that leap.

Revealing the Truth of Anode Failure: Cracks Precede Lithium Penetration

Advanced characterization has provided subversive insights into anode-side dendrite and interface failure:

Neutron Depth Profiling (NDP): This technique can quantitatively track lithium concentration. Studies have confirmed that the intrinsic electronic conductivity of some solid electrolytes (like LLZO) is a key factor in inducing lithium dendrite growth inside the electrolyte bulk.

Synchrotron X-ray Computed Tomography (XCT): This provides stunning 3D visualization. It has revealed a long-misunderstood process: under an electric current, cracks first initiate and propagate within the electrolyte, and only then does lithium metal penetrate them. This overturns the traditional belief that "lithium penetration drives the crack," and highlights the critical importance of mechanical properties in suppressing dendrites.

A Deeper Look at the Cathode: "Internal Microcracks" and "Interfacial Side Reactions"

On the more complex cathode side, in-situ techniques have revealed unique failure modes:

Transmission X-ray Microscopy and X-ray Near-Edge Absorption Spectroscopy (TXM-XANES): This combination found that during long-term cycling, microcracks form inside the cathode active material particles. These newly exposed surfaces cannot be wetted by the solid electrolyte, creating "isolated islands" and causing a loss of ion transport pathways—a primary cause of performance decay.

In-situ XAS and XRD: These techniques have visually confirmed the effectiveness of interfacial coatings (like LiNbO₃). They proved that nano-coatings can effectively suppress detrimental side reactions between high-energy NCM811 cathodes and sulfide electrolytes, thereby stabilizing the interface.

Visualizing the Electrolyte and Device: From "Crack Deflection" to "Thermal Runaway"

In-situ characterization can also reveal how components work together at the device level:

Mechanical Design of Electrolytes: XCT technology has clearly observed that in cleverly designed multilayer electrolyte structures, cracks will deflect laterally or be filled by reaction products upon reaching an interlayer interface. This "circuit breaker"-like mechanism can effectively block catastrophic dendrite penetration.

Real-Time Observation of Thermal Runaway: By coupling X-ray imaging with calorimetry, researchers have, for the first time, observed the internal behavior of a solid-state battery during thermal runaway. This provides the most critical data for assessing its safety risks and guiding safe design.

Summary and Outlook: From "Seeing" to "Predicting"

This review systematically demonstrates how synchrotron and neutron techniques help us directly link the macroscopic electrochemical performance of ASSBs to their microscopic structural and chemical evolution. These powerful tools allow us to "see" the true working mechanisms inside the battery, providing unprecedented insights for the rational design of high-performance systems.

In the future, characterization will evolve toward "multi-modal" (detecting multiple signals at once) and "AI-driven" (efficiently processing massive data sets) approaches. The ultimate goal is to establish a standardized workflow to systematically solve the multi-scale challenges of ASSBs and truly drive them toward practical application.

A deep understanding of the battery's internal "black box" is the bridge connecting cutting-edge research with industrial-scale production. LIMX Power is committed to using the most advanced R&D methods and profound mechanistic insights to drive the engineering and commercialization of next-generation high-energy-density batteries.

Literature Details

Probing All-Solid-State Batteries with Real-Time Synchrotron and Neutron Techniques, Advanced Energy Materials, 2025, e04045. https://doi.org/10.1002/aenm.202504045

Author Biographies

Suzhe Liang (First Author): Postdoctoral Fellow at Ningbo Institute of Technology, Eastern. He received his Dr. rer. nat. from the Technical University of Munich (TUM) in 2024. His research includes ASSB interfaces, anode materials for Li/Na-ion batteries, and in-situ X-ray scattering techniques.

Yipeng Sun: Research Associate Professor at Ningbo Institute of Technology, Eastern. He received his Ph.D. in Mechanical and Materials Engineering from Western University (Canada) in 2022. His research includes atomic/molecular layer deposition, interface design for next-gen batteries, and synchrotron-based characterization.

Xueliang Sun: Foreign Member of the Chinese Academy of Engineering, Fellow of the Royal Society of Canada, and Fellow of the Canadian Academy of Engineering. He is a Chair Professor and Dean of the Institute of Materials and Energy at Ningbo Institute of Technology, Eastern. His research focuses on solid-state batteries and fuel cells. He has been named a Clarivate "Global Highly Cited Researcher" for 6 consecutive years.

Changhong Wang: Assistant Professor at Ningbo Institute of Technology, Eastern. He received the prestigious Banting Postdoctoral Fellowship in 2022. His research focuses on key materials and technologies for ASSBs. He has been listed in the "World's Top 2% Scientists" for 4 consecutive years.

Comments